Stop Fixing Symptoms: Employ the 5 Whys to Get to the Root of Business Problems

The Japanese industrialist Sakichi Toyodo, founder of Toyota Industries, developed a technique in the 1930s to identify root issues that inhibited success. He called it the 5 Whys. Toyota and many other organizations implement this Root cause analysis (RCA) technique today. Often as organizations grow, the management becomes removed from the day to day work that provides the value to the business. When problems arise, the leaders are not informed in a way that will equip them to make decisions to take appropriate counter-measures. This technique preserves precious time resources because it avoids quick-fix solutions that may only solve a few symptoms and not the underlying problems.

How to Implement 5 Whys:

Team up

The 5 Whys are based on a “go and see” philosophy: leaders take a deep dive into the heart of the problem to give them an understanding of what documentable things are actually happening in the business, that they observe on their own, not gathered around the board room from people who think they know. Assemble a team of people who are familiar with the problem or process that you are trying to fix. Additionally, choose someone who will act as a facilitator who will keep the team on track to identify counter-measures. Counter-measures address the root problem as a set of actions to prevent the problem from happening again.

Define the Problem

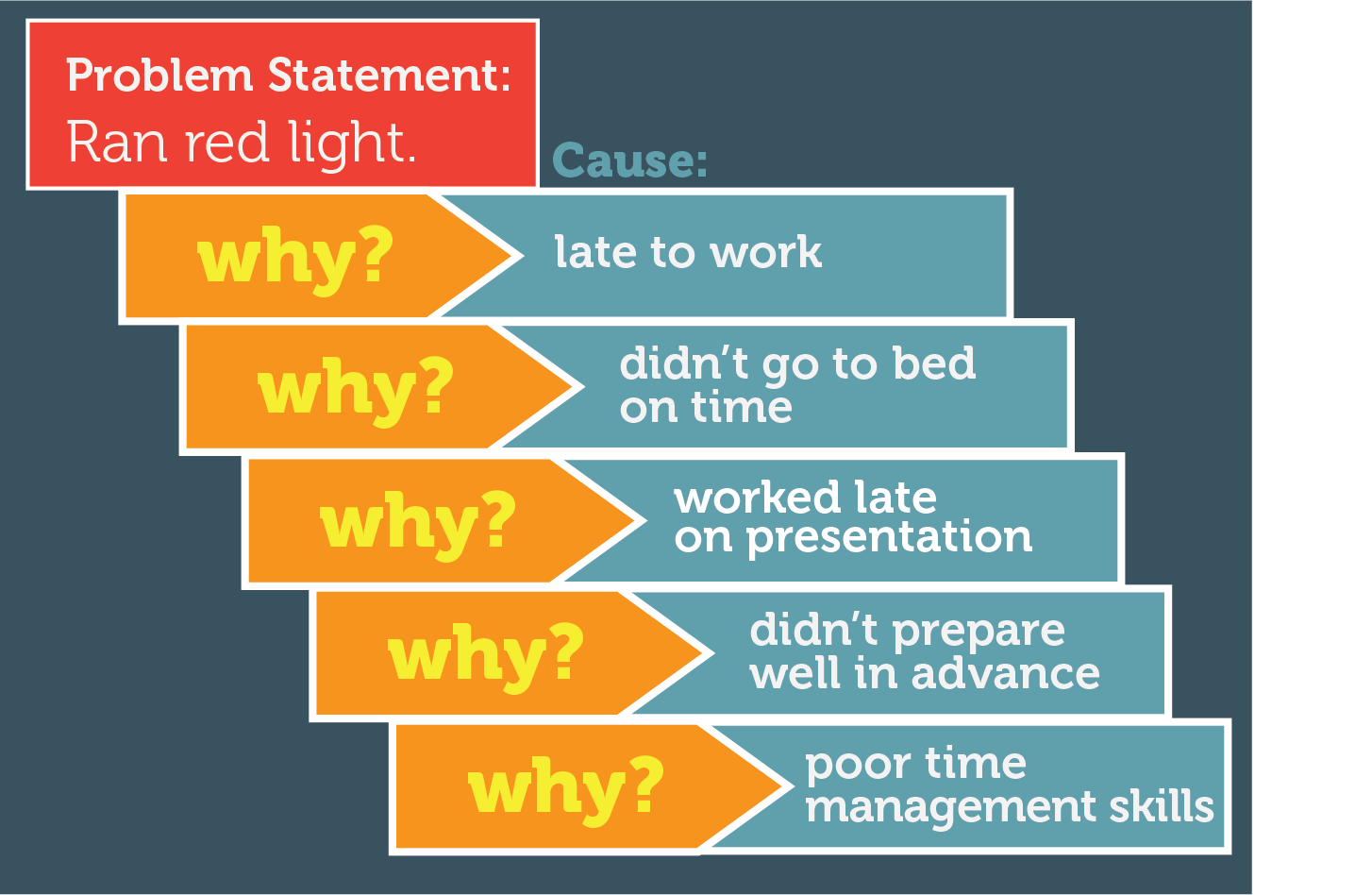

You may have many symptoms to one problem: the facilitator will guide the group to agree on the problem statement. A well-defined problem statement will save time- so spend time here. Write down the problem statement with space next to it.

Ask Why

Next to the problem statement, write: WHY? Write the answer (the cause of the problem) below that WHY. Repeat this and ask why again- writing the cause below each why. At the end of this process you will have your root cause.

Define Counter-measures

After you have the determined the causes of your problem, the next step is to create counter-measures for those causes. Often, a counter-measure that adresses the root cause will address the preceeding causes asd well. Other times it is necessary to create counter-measures for each cause.

Assign Action Responsibilities

For each counter-measure created, the facilitator will assign an owner who will take responsibility to address the cause, create milestones, and monitor outcomes.

Monitor Results

As leaders, we rely on our teams to take action- this is an important component. Create a review date to reconvene and discuss results. Have problems resolved? Perhaps it is time to make adjustments and review if the counter-measures were ineffective. If you find the counter-measures were not effective, review the problem statement and causes and repeat the exercise. Record your findings to share with the rest of your organization so all can learn from the exercise and thank your team for their contribution. The 5 Whys can be used as an initial technique and incorporated into other processes like LEAN or Six Sigma.